5X Improvement in Engine Manufactering QA

By listening to Engine sound, AcousticDL™ detects the defective engine for our Automotive manufacture’s assembly line in seconds. Can you hear the difference between good vs defective engine?

3 week faster IPV, In process verification, of composite parts

By listening to a composite slab’s impact sound, AcousticDL™ detects delamination and other defects improving IPV by 3 weeks saving manufacturing costs. Listen to a good and a delaminated part’s sound.

Reliably detect weather conditions by listening

By remotely listening AcousticDL™ reliability classifies the weather conditions: rain, hail, snow, or strong storm. Deployed in weeks for maintenance and insurance fraud detection, listen to two typical recordings: is it hail or rain?

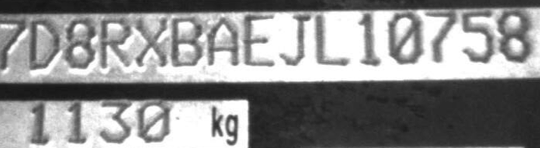

Automated frame number reader and verification

Read characters on a metal/other surfaces in a difficult-to-read environments using a ergonomic handheld/fixed device without using any ambient lights, which is not possible using standard OCR solutions.

Reduce the verification time to a second without requiring human intervention using mSense’s VisionDL™ for an automobile manufacturing plant.